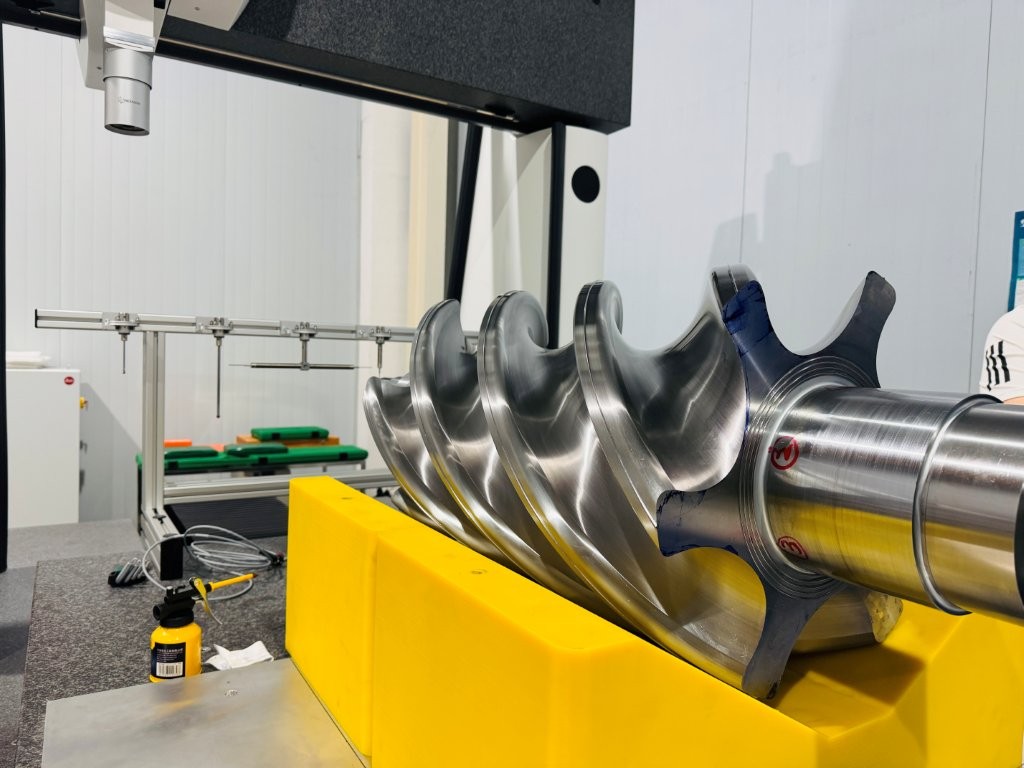

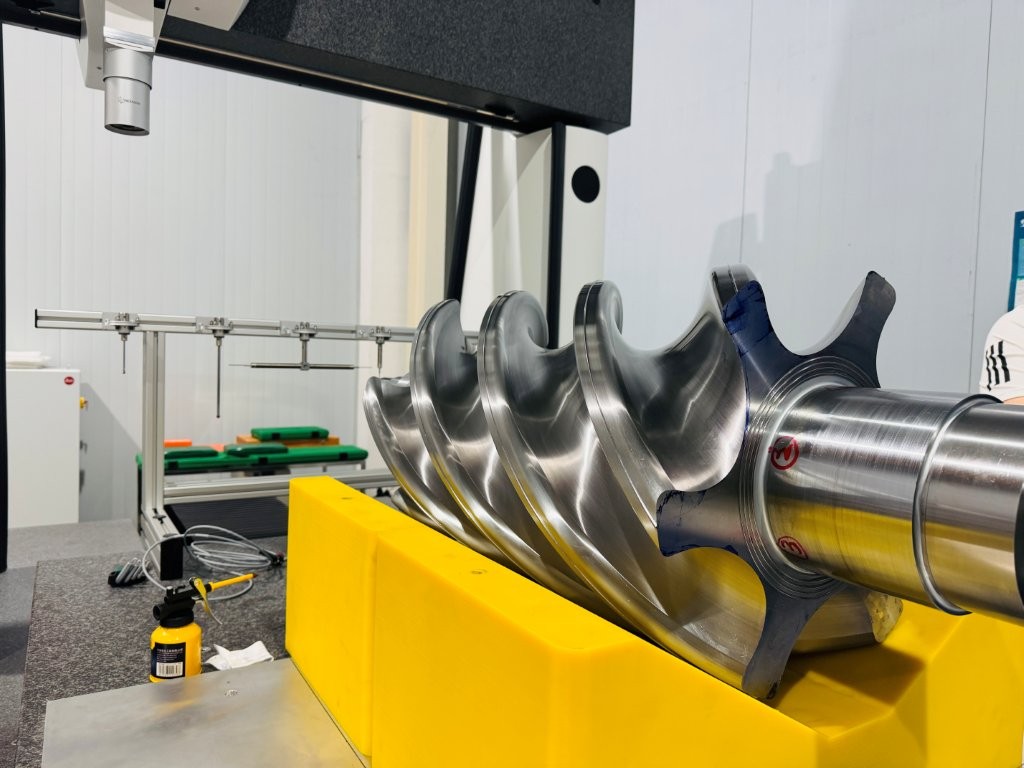

In the fast-paced world of industrial manufacturing, screw rotors stand as the heart of air and gas compressors. These precision-engineered components must seamlessly integrate with leading global brands like Atlas Copco, Ingersoll Rand, and Kaeser. But how do Chinese trading companies, including suppliers like WALKSON, guarantee this compatibility? This blog dives into the meticulous processes that ensure screw rotors meet international standards, delivering reliability and performance. Whether you're in oil & gas, petrochemicals, or HVAC, understanding these strategies can optimize your supply chain.The Critical Role of Screw Rotors in Compressor PerformanceScrew rotors are twin helical screws that compress air or gas through precise meshing. Compatibility issues can lead to inefficiencies, downtime, or failures. Chinese trading companies address this by prioritizing precision engineering from the start. At WALKSON, we specialize in forging and machining screw rotors that align perfectly with global compressor brands.Our forging capabilities ensure rotors withstand high pressures and temperatures. By using advanced alloys like stainless steel and nickel-based materials, we match the durability required by brands such as Gardner Denver. This foundation sets the stage for flawless integration.Screw Rotor Forging Process

Image: WALKSON's hot forging process for screw rotors, ensuring material integrity.Reverse Engineering: The Key to Perfect FitOne primary method Chinese trading companies employ is reverse engineering. This involves disassembling OEM rotors from global compressor brands to create detailed blueprints.3D Scanning and Measurement: Using CMM (Coordinate Measuring Machines) and laser scanners, profiles are captured with micron-level accuracy.

Material Analysis: Spectroscopy identifies exact compositions, replicating them in production.

Tolerance Matching: Ensuring pitch, diameter, and helix angles match precisely.

WALKSON excels here with our closed die forging techniques. We've successfully reverse-engineered rotors for Sullair compressors, reducing lead times by 30%. For authoritative insights, refer to the American Society of Mechanical Engineers (ASME) standards on rotary compressors.This approach not only ensures compatibility but also allows cost-effective alternatives without compromising quality.Adhering to International Standards and CertificationsCompatibility isn't just about dimensions—it's about compliance. Chinese trading companies secure certifications like ISO 9001, API, and PED to build trust.WALKSON holds multiple certifications, including DNV and ABS for marine applications. We test screw rotors under simulated conditions:Dimensional Inspection: Using Faro arms for 100% verification.

Non-Destructive Testing (NDT): Ultrasonic and magnetic particle testing to detect internal flaws.

Performance Trials: Dyno testing mimics real-world compressor operations.

These steps guarantee rotors fit global brands like Quincy or Hitachi. Industry resource: ISO 8573-1 for compressed air quality.NDT Inspection Diagram

Diagram: WALKSON's NDT process flow for screw rotor compatibility testing.Advanced Manufacturing Technologies for PrecisionTo achieve screw rotor compatibility with global compressor brands, Chinese companies invest in CNC machining and 5-axis milling. WALKSON's state-of-the-art facility in China features:Multi-Axis CNC Centers: For complex geometries.

Heat Treatment Furnaces: Controlled quenching for hardness (HRC 55-62).

Surface Coatings: DLC or PVD to reduce friction, matching OEM specs.

Our machining services have supplied rotors to European clients integrating with Bitzer systems. This tech ensures backlash-free meshing, vital for energy efficiency.A study by the Compressed Air and Gas Institute (CAGI) highlights how precise rotor profiles can improve efficiency by up to 15%.Quality Control and Supply Chain IntegrationRigorous QC is non-negotiable. Chinese trading companies implement:In-Process Checks: Real-time monitoring during forging and grinding.

Final Assembly Simulation: Pairing rotors to verify clearance (typically 0.05-0.1 mm).

Traceability Systems: From raw material to delivery.

WALKSON's ERP system tracks every screw rotor, ensuring compatibility documentation for audits. We partner with logistics experts for global shipping, minimizing delays.For mining applications, our rotors compatible with Joy compressors endure abrasive environments—explore our mining components.Case Study: WALKSON's Success with Global BrandsRecently, WALKSON delivered 50 sets of screw rotors to a U.S. client for Ingersoll Rand upgrades. Through reverse engineering and API-compliant forging, we achieved 99.9% compatibility, cutting costs by 25%. Client testimonial: "Seamless integration—no vibrations or leaks."This exemplifies how Chinese trading companies bridge East-West manufacturing gaps.Why Choose WALKSON for Your Screw Rotor Needs?As a leader in precision engineered parts, WALKSON ensures screw rotors exceed global compressor brand requirements. Our one-stop solution—from forging to finishing—guarantees compatibility, quality, and speed.Ready to optimize your compressors? Visit www.walkson.com/contact for a custom quote. Follow us on LinkedIn and X for industry updates!

English

English  Deutsch

Deutsch  français

français  русский

русский  فارسی

فارسی  العربية

العربية  Español

Español  日本語

日本語  한국어

한국어  italiano

italiano  português

português  dansk

dansk  Suomi

Suomi