1. Steel Sand Casting Process

The steel sand casting process can be broken down into the following key steps:

a. Mold Preparation

Pattern Creation: The first step involves creating a pattern of the desired part, typically made from materials like wax, wood, or metal. The pattern is designed to account for the shrinkage of steel during cooling.

Mold Formation: The pattern is then covered with a special mixture of sand (often silica) and a bonding agent. This mold is made by packing the sand tightly around the pattern, which can be done manually or through mechanized processes.

Core Creation (if needed): In some cases, cores made of sand and binding agents are placed inside the mold to create hollow sections in the final casting.

Mold Drying: The mold is then dried or hardened, depending on the specific process used, such as air-set molding or shell molding.

b. Melting the Steel

Steel is typically melted in an induction furnace or electric arc furnace. The steel is heated to the desired temperature, usually between 1,400°C and 1,600°C (2,552°F and 2,912°F), depending on the type of steel being cast.

c. Pouring the Molten Steel

Once the steel is molten, it is carefully poured into the prepared sand mold. The molten steel fills the cavity of the mold, taking the shape of the pattern. The pouring process must be precise to avoid defects like porosity or inclusions.

d. Cooling and Solidification

The molten steel cools and solidifies within the mold. As the steel cools, it contracts, and any shrinkage is compensated for by the mold design.

e. Mold Removal

Once the steel has completely cooled and solidified, the sand mold is broken apart, and the casting is removed. This process may involve shaking or vibrating the mold to break it up and extract the casting.

f. Finishing and Inspection

After the casting is removed, it often requires additional finishing steps, such as:

Cleaning: Sand and other debris are removed from the surface.

Machining: The casting may require machining to achieve tight tolerances and a smooth finish.

Heat Treatment: Depending on the desired mechanical properties, the casting may undergo heat treatment processes like annealing, quenching, or tempering.

2. Applications of Steel Sand Casting

Steel sand casting is used to produce a wide variety of parts across numerous industries. Its ability to create complex shapes with high strength makes it ideal for applications requiring both durability and precision. Some of the key applications include:

a. Automotive Industry

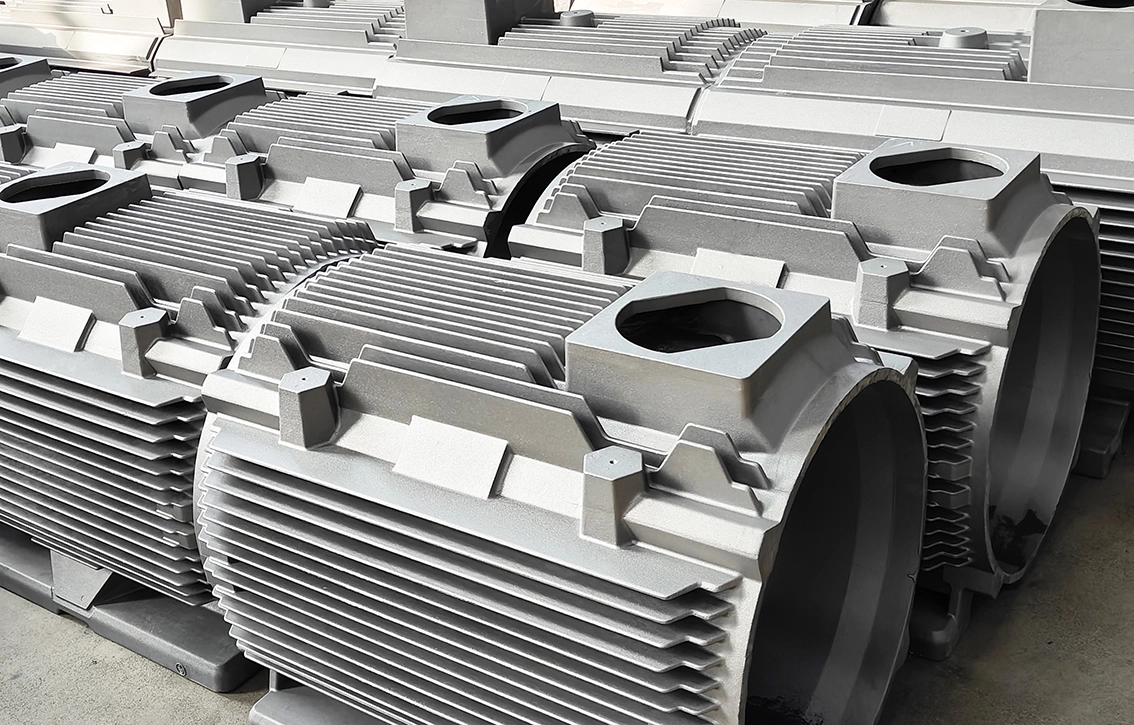

Engine Blocks: Sand casting is commonly used to produce large engine blocks, cylinder heads, and other heavy automotive components.

Transmission Parts: Components such as housings, gears, and shafts can also be produced using sand casting.

Suspension Components: Parts like control arms, knuckles, and brackets that must withstand high stress and load.

b. Heavy Machinery

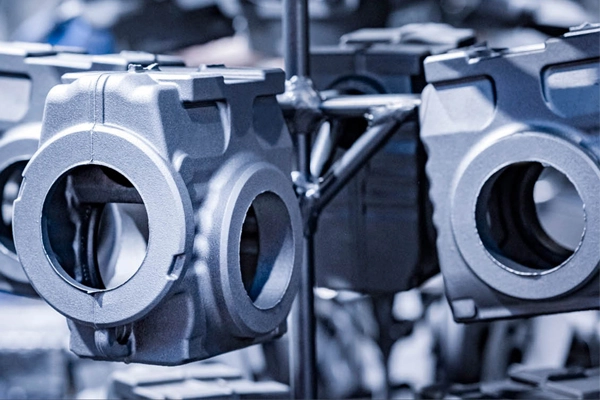

Pump Bodies and Valve Bodies: Sand casting is ideal for producing pump and valve bodies, which require a high degree of strength and resistance to wear.

Gearbox Housings: Large housings for gearboxes in industrial machinery can be effectively cast in steel using sand molds.

Crane Components: Parts used in cranes, such as gears and winch components, which must have high load-bearing capabilities.

c. Marine Industry

Propeller Housings: Castings for propeller housings and other components exposed to seawater are often made using steel sand casting due to its excellent corrosion resistance.

Ship Components: Parts like rudder blades, hull structures, and engine components are made from sand-cast steel.

d. Power Generation

Turbine Parts: Components for steam or gas turbines, including blades, rotors, and casings, are often made by steel sand casting due to the high heat and mechanical stresses they endure.

Piping and Fittings: Sand casting is commonly used to produce steel piping systems, valves, and fittings for power plants.

e. Industrial Equipment

Machine Tool Parts: Steel sand casting can create machine bed plates, frames, and other components used in heavy-duty industrial machinery.

Mining Equipment: Parts such as crushers, grinding mills, and conveyor components are often made using this method.

f. Oil and Gas Industry

Drill Bits: Cast steel drill bits used for oil and gas exploration are often made using sand casting.

Pipe Flanges: Steel flanges for oil and gas pipelines are commonly made using sand casting due to their need for strength and resistance to high-pressure conditions.

3. Advantages of Steel Sand Casting

Versatility: Sand casting can produce complex and intricate shapes with a high degree of flexibility in terms of size and weight.

Cost-Effective: It is one of the most cost-effective casting methods, especially for large production runs and single-unit parts.

Strong Materials: Steel castings are durable and can withstand high loads, making them suitable for demanding applications in heavy industries.

Large Components: Sand casting is particularly suited for producing large, heavy parts that would be difficult or costly to produce with other methods.

Customization: The process allows for the creation of highly customized parts based on specific design requirements.

Material we can do but not limited to:

GB(ZG200-400,ZG230-450,ZG270-500,ZG310-570,ZG20SiMn,ZG35CrMo, ZG30Cr26Ni5, ZG35Cr26Ni12, ZG40Cr25Ni20, ZG40Cr30Ni20, ZG45Ni35Cr26, ZG1Cr13, ZG2Cr13, ZG00Cr18Ni10, ZG0Cr18Ni9, ZG1Cr18Ni9Ti, ZG0Cr18Ni12Mo2Ti, ZG1Cr18Ni12Mo2Ti)

BS(A1, A2, 161 Grade430, 161Grade480, 621, 622, 625, 309C35, 410C21, 420C29, 304C12, 304C15, 302C25, 347C17, 316C12)

DIN(GS-38, GS-45, GS-52, GS-60, GS-20Mn5, GS-34CrMo4, GS-C25, GS-17CrMo5-5, GS18CrMo9-10, G-X40CrNiSi27-4, G-X40CrNiSi25-12, G-X40CrNiSi2520, G-X45CrNiSi35-25, G-X7Cr13, G-X10Cr13, G-X20Cr14, G-X2CrNi18-9, G-X6CrNi18-9, G-X10CrNi18-8, G-X5CrNiNb18-9, G-X6CrNiMo18-10, G-X5CrNiMoNb18-10)

ASTM( 415-205(60-30), 450-240(65-35), 485-275(70-40), (80-40), LCC, Grade WCA, Grade WCB, Grade WC6, Grade WC9, Grade WC5)

ASTM/ACI(HD, HH, HK, HK40, HL, HP, CA-15, CA-40, CF-3, CF-8, CF-20, CF-8C, CF-3M, CF-8M)

UNS(J03000, J03101, J02501, J05002, J02505, J02502, J03002, J12072, J21890, J22000, J93005, J93503, J94224, J94204, J94604, J95705, J91150, J91153, J92500, J92600, J92602, J92710, J92800, J92900)

Products: steel casting, alloy steel casting, stainless steel casting products

English

English  Deutsch

Deutsch  français

français  русский

русский  فارسی

فارسی  العربية

العربية  Español

Español  日本語

日本語  한국어

한국어  italiano

italiano  português

português  dansk

dansk  Suomi

Suomi