Annealing Process for Castings and Forgings

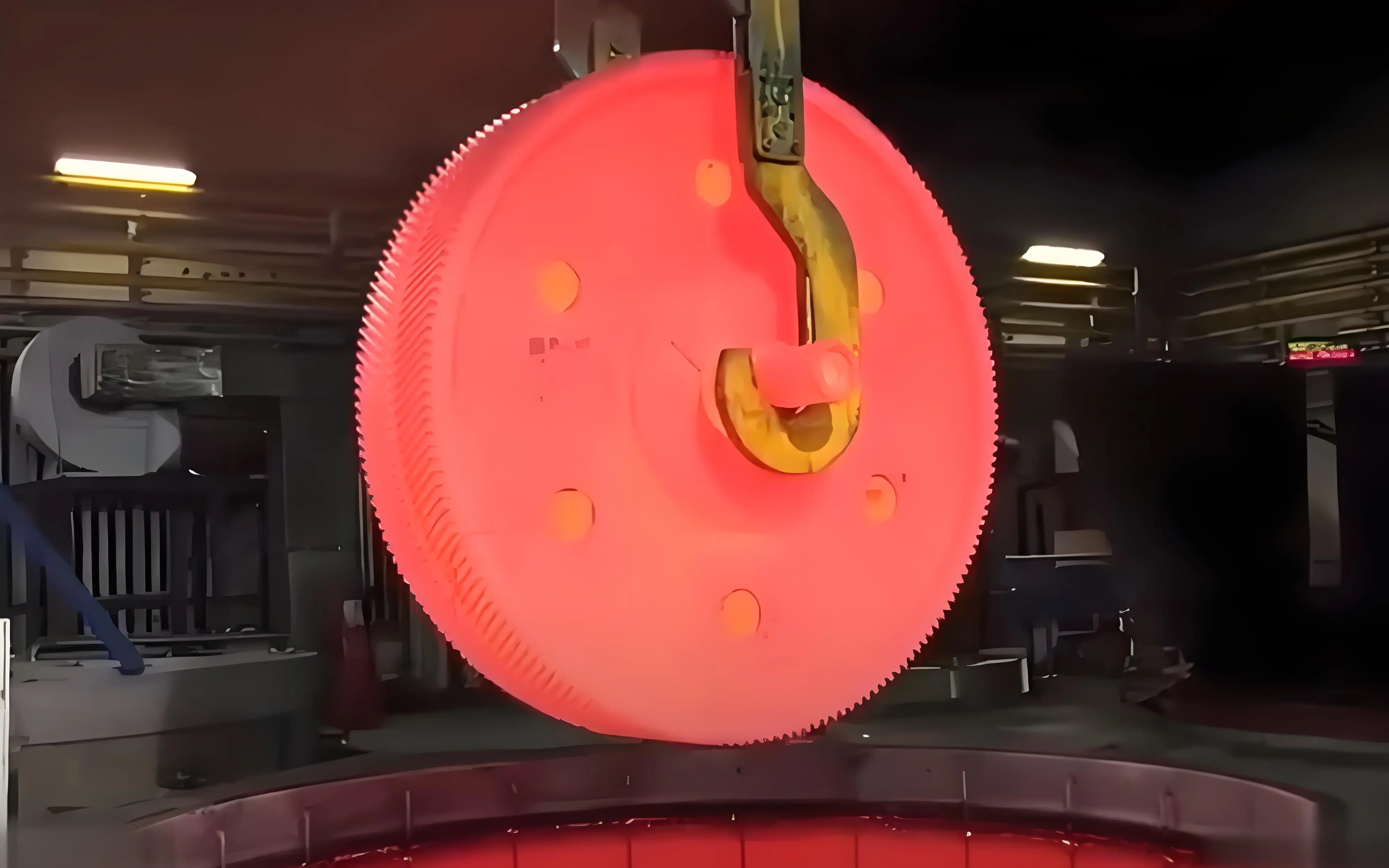

1. Heating:

The material is gradually heated to a specific temperature, typically between 600°C to 900°C (1,100°F to 1,650°F), depending on the material type and the desired effect. This temperature is carefully controlled to avoid overheating, which could lead to unwanted changes in the material structure.

2. Soaking:

Once the target temperature is reached, the material is held (soaked) at that temperature for a predetermined period. The soaking time allows the material to achieve uniform temperature distribution, ensuring that the entire part undergoes consistent structural changes.

3. Cooling:

After soaking, the material is slowly cooled, typically in the furnace itself (controlled cooling), to prevent the formation of new stresses that could result from rapid temperature changes. Slow cooling minimizes the risk of cracking or distortion, making it particularly useful for large or complex parts.

In some cases, the material may be cooled in air or a controlled environment, depending on the specific requirements of the application and the material used.

Types of Annealing Processes for Castings and Forgings

While the general process outlined above applies to most materials, specific annealing techniques can be employed based on the characteristics of the alloy and the final product requirements. Some common types of annealing used for castings and forgings include:

1. Full Annealing:

Purpose: To soften the material and improve its ductility and machinability, particularly useful for steels and high-carbon alloys.

Process: The material is heated to a temperature above its critical range (for steel, this is typically around 750°C to 900°C) and then slowly cooled in the furnace. This process refines the grain structure and provides uniform properties across the material.

2. Stress-Relieving Annealing:

Purpose: To relieve internal stresses induced by casting or forging operations without significantly altering the material’s hardness or strength.

Process: The material is heated to a sub-critical temperature (usually around 550°C to 650°C) and held for a short period before being allowed to cool slowly. This reduces the risk of distortion or cracking during subsequent processing or in service.

3. Process Annealing:

Purpose: To reduce hardness and improve ductility for materials that will undergo further processing or machining.

Process: The material is heated to a lower temperature (usually between 550°C to 650°C) and held for a short time before being allowed to cool. This is commonly used for mild steel and low-carbon alloys.

4. Spheroidizing:

Purpose: To produce a spheroidized (rounded) microstructure, which improves the machinability and formability of high-carbon steels.

Process: The material is heated to a temperature below its eutectoid point, followed by slow cooling. This results in the formation of a microstructure composed of spherical cementite particles, making the material softer and easier to machine.

Benefits of Annealing for Castings and Forgings

1. Enhanced Mechanical Properties:

Annealing improves ductility, toughness, and hardness, which are essential for ensuring that castings and forgings can withstand mechanical stress and fatigue during service.

2. Improved Machinability:

By softening the material, annealing reduces the wear on cutting tools and minimizes the risk of work hardening during machining processes, resulting in smoother finishes and more accurate tolerances.

3. Stress Relief and Dimensional Stability:

By relieving internal stresses, annealing ensures that components maintain their dimensional stability throughout subsequent processing stages, reducing the likelihood of warping or distortion during machining or welding.

4. Homogeneous Properties:

5. Optimized Performance:

By refining the material's microstructure, annealing enhances the overall performance and longevity of the part, making it more resistant to wear, fatigue, and corrosion.

Applications of Annealing in Castings and Forgings

Annealing is widely used in a variety of industries where castings and forgings must meet high standards of quality and performance. Some key applications include:

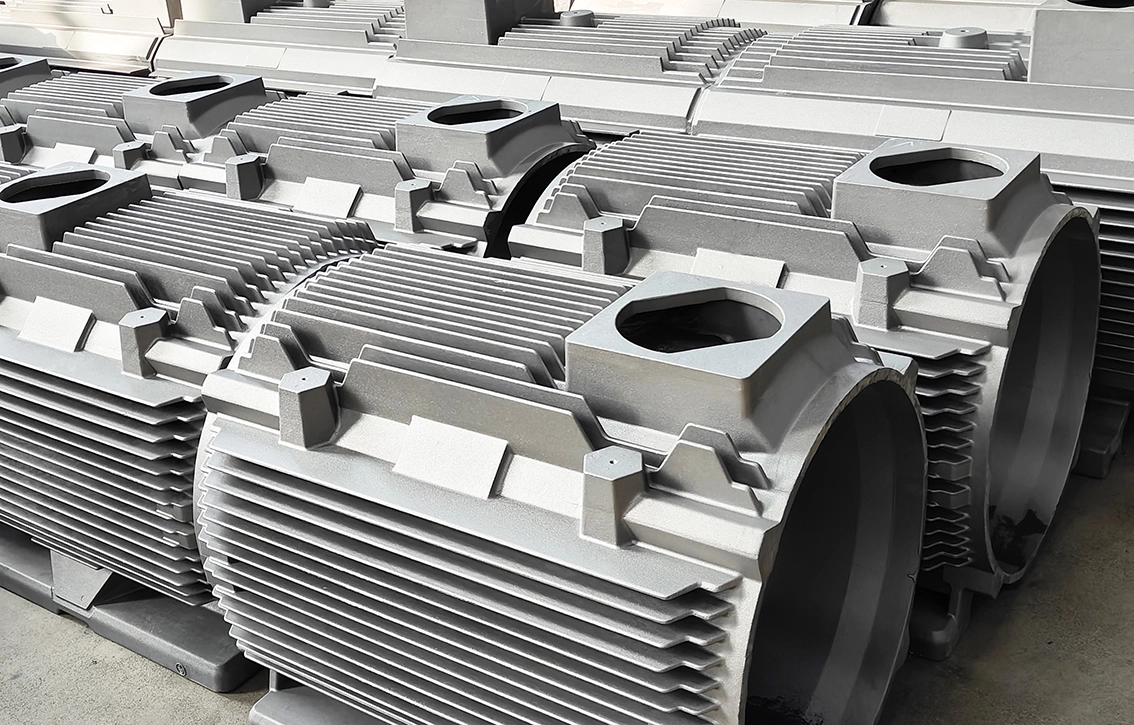

Automotive Industry: Engine components, structural parts, and suspension components that require high strength, toughness, and improved machinability.

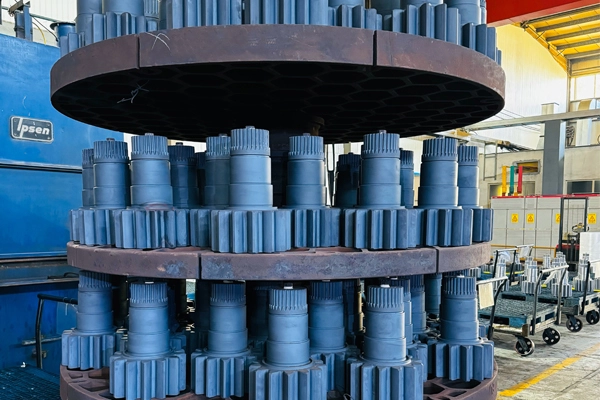

Heavy Machinery: Components used in construction, mining, and agricultural machinery that must withstand high stress and harsh operating environments.

Tooling & Dies: Tools, dies, and molds used in manufacturing processes that need to be highly durable, resistant to wear, and capable of precise machining.

Oil & Gas: Parts for drilling and exploration equipment that need to maintain high strength and corrosion resistance in harsh environmental conditions.

English

English  Deutsch

Deutsch  français

français  русский

русский  فارسی

فارسی  العربية

العربية  Español

Español  日本語

日本語  한국어

한국어  italiano

italiano  português

português  dansk

dansk  Suomi

Suomi