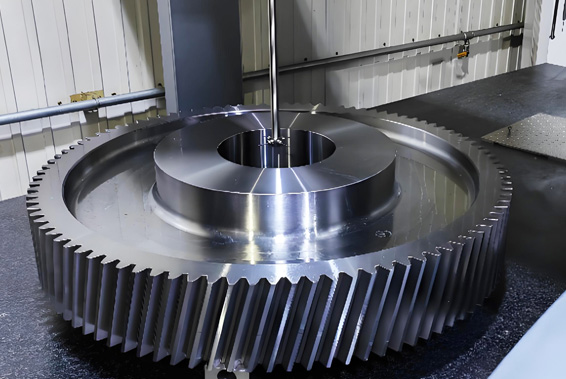

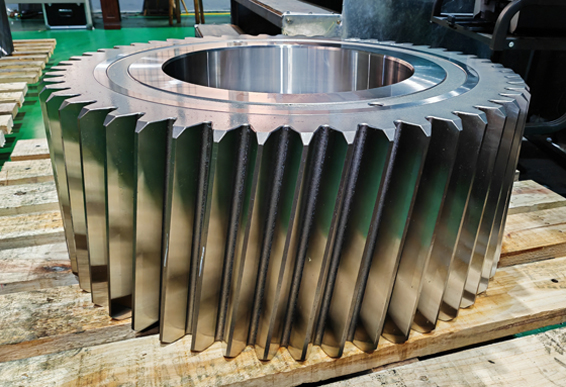

Forged Helical Gears: Precision-Engineered for Smooth Power Transmission

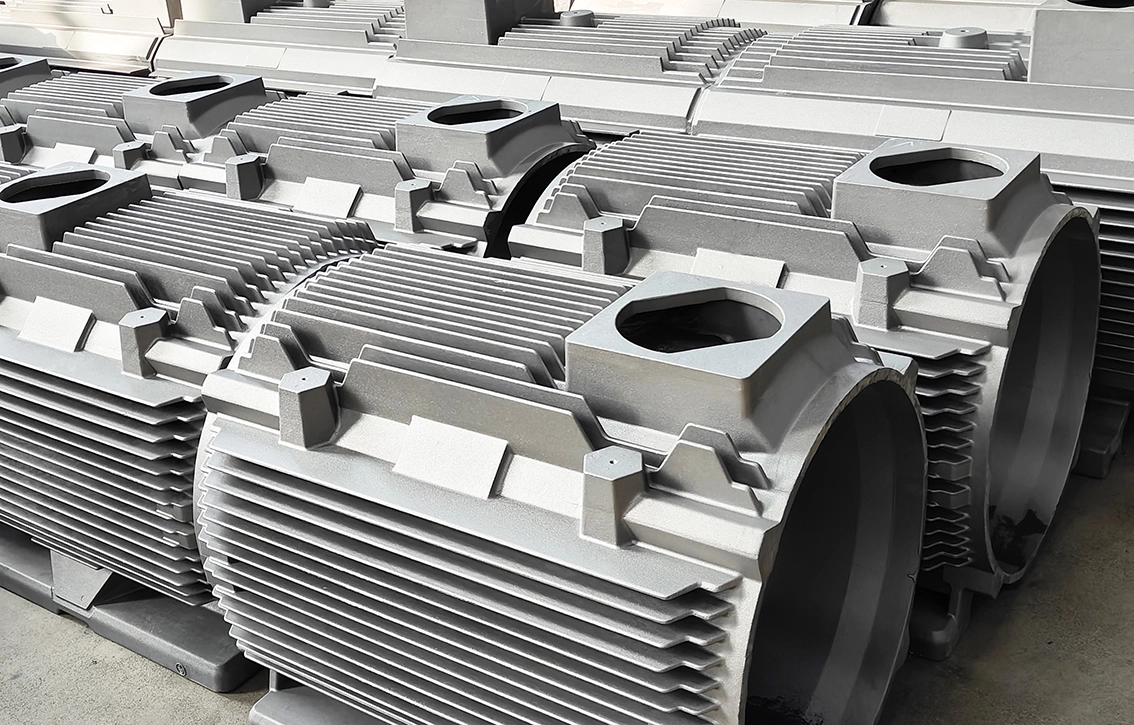

WALKSON is a leading global supplier of high-quality forged helical gears, designed to meet the rigorous demands of industries such as mining, heavy machinery, automotive, and renewable energy. Our helical gears are crafted with precision to deliver smooth, quiet operation and exceptional durability, making them the preferred choice for efficient power transmission. By choosing WALKSON, you partner with a trusted manufacturer committed to quality, customization, and compliance with international standards. For inquiries, contact us at info@walkson.com (mailto:info@walkson.com) or via WhatsApp/WeChat for personalized consultation.

Product Description and Function

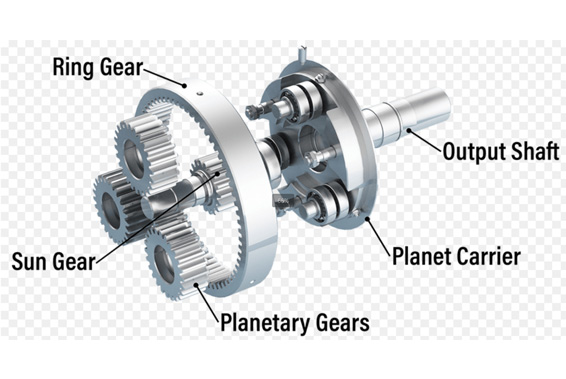

Forged helical gears are cylindrical gears with angled teeth that form a helix, enabling gradual tooth engagement for smoother and quieter operation compared to spur gears. They are designed to transmit rotational motion and torque between parallel or crossed shafts, offering high load-carrying capacity and efficiency. Helical gears are ideal for applications requiring high-speed, high-torque transmission, such as wind turbines, automotive transmissions, industrial gearboxes, and mining equipment. WALKSON’s forged helical gears are engineered for superior strength, wear resistance, and precision, ensuring reliable performance in demanding environments.

Key Features:

· Smooth Operation: Angled teeth ensure gradual engagement, reducing noise and vibration.

· High Load Capacity: Forged construction enhances durability for heavy-duty applications.

· Versatility: Suitable for parallel or crossed shaft configurations in diverse industries.

· Customizability: Tailored helix angles, tooth profiles, and materials to meet specific requirements.

Commonly Used Material Grades (EN and ASTM Standards)

WALKSON selects premium materials to ensure our forged helical gears meet stringent performance standards, with material choices guided by application demands such as load, speed, and environmental conditions. Below are commonly used material grades compliant with EN and ASTM standards:

· EN Standards:

· EN 10083-2 C45E: Medium carbon steel offering good strength and toughness, suitable for general-purpose helical gears.

· EN 10083-3 42CrMo4: Chromium-molybdenum alloy steel with excellent fatigue resistance and impact strength, ideal for high-load applications.

· EN 10083-3 34CrNiMo6: High-strength alloy steel with superior toughness, used in heavy-duty gears for mining and energy sectors.

· ASTM Standards:

· ASTM A29 1045: Medium carbon steel with good machinability and wear resistance, commonly used in industrial gears.

· ASTM A322 4140: Chromium-molybdenum steel offering high strength and durability for demanding applications.

· ASTM A322 4340: Nickel-chromium-molybdenum alloy steel with exceptional toughness and fatigue resistance, ideal for critical components.

For specialized applications, WALKSON offers materials like stainless steel (e.g., ASTM A182 F304/F316) for corrosion resistance or high-manganese steel for extreme wear. All materials comply with EN 10293, EN 10228, ASTM A788, ensuring traceability and quality.

Modern and Standardized Manufacturing Process

WALKSON employs a state-of-the-art manufacturing process for forged helical gears, adhering to international standards to ensure precision, reliability, and consistency. Each stage is meticulously controlled, from raw material selection to final inspection, with advanced quality assurance protocols like APQP (Advanced Product Quality Planning), PPAP (Production Part Approval Process), PFMEA (Process Failure Mode and Effects Analysis), and First Article Trial (FAT) implemented to mitigate risks and validate production readiness.

Manufacturing Process Steps:

· Raw Material Inspection:

· Standards: EN 10204 (Type 3.1/3.2 certification), ASTM A388.

· Process: Incoming materials undergo chemical composition analysis using spectrometry and ultrasonic testing (UT) to detect internal defects.

· Equipment: Optical emission spectrometers, ultrasonic flaw detectors.

· Forging:

· Standards: EN 10243-1, ASTM A788, ISO 2768.

· Process: Closed-die forging at controlled temperatures enhances grain structure and mechanical properties, ensuring high strength with minimal material waste.

· Equipment: Hydraulic forging presses (up to 15,000 tons), induction heating furnaces.

· Heat Treatment:

· Standards: EN 10083, ASTM A29, SAE J404, ISO 6336.

· Process:

· Normalizing: Refines grain structure for improved machinability and uniformity.

· Quenching and Tempering: Achieves hardness (200–350 HB) and toughness for high-load applications.

· Carburization: Diffuses carbon into the surface for a hard, wear-resistant layer (60–62 HRC) with a tough core, ideal for heavy-duty gears.

· Nitriding: Forms a hard surface case (65–70 HRC) with excellent fatigue resistance and minimal distortion, suited for precision gears.

· Nitrogen Case Hardening: Enhances surface hardness and corrosion resistance for harsh environments.

· Vacuum Heat Treatment: Conducted in an oxygen-free environment to prevent oxidation, ensuring clean surfaces and precise metallurgical properties for aerospace and energy applications.

· Equipment: Continuous heat treatment furnaces, vacuum furnaces, nitriding furnaces, quenching tanks, induction heating systems.

· Quality Control: Automated monitoring of temperature, time, and atmosphere prevents distortion. Hardness testing (Rockwell/Brinell) and metallographic analysis verify case depth and microstructure.

· Machining:

· Standards: ISO 2768, DIN 3962 (gear quality class 6–8).

· Process: Advanced machining techniques ensure precise tooth profiles and surface finish (Ra 0.4–1.6). Processes include:

· Gear Hobbing: Performed on Gleason machines for high-precision helical tooth cutting, ensuring accurate geometry and helix angles.

· Gear Shaping: Utilizes Gleason equipment for complex tooth profiles, offering flexibility for custom designs.

· Precision Grinding: Conducted on Kapp Niles grinders to achieve superior surface finish and tight tolerances, enhancing gear performance and longevity.

· CNC Milling: Supports additional machining for gear blanks and features.

· Equipment: Gleason gear hobbing and shaping machines, Kapp Niles precision grinders, 5-axis CNC milling machines, CNC gantry machining centers (up to 20m long, 5m wide, 4m high).

· Surface Treatment:

· Standards: ISO 12944, ASTM B117.

· Process: Optional treatments like coating or shot peening enhance wear and corrosion resistance.

· Equipment: Shot blasting machines, coating systems.

· Final Inspection and Testing:

· Standards: EN 10228, ASTM A275, DIN EN ISO 16859.

· Process: Dimensional checks, non-destructive testing (NDT), and performance testing ensure compliance. Gear-specific inspections include:

· Gear Inspection: Conducted using Zeiss CMM for precise dimensional verification and Gleason GMM for comprehensive gear metrology, including tooth profile, helix angle, pitch, and runout.

· Equipment: Zeiss coordinate measuring machines, Gleason GMM gear measuring machines, magnetic particle testers, 3D laser scanners.

Quality Assurance Protocols:

· APQP: Structured planning aligns manufacturing with customer requirements, ensuring robust process design.

· PFMEA: Identifies potential failure modes in forging and machining, implementing preventive controls.

· PPAP: Comprehensive documentation, including control plans, process flow diagrams, and capability studies (Cpk ≥ 1.33), validates production readiness.

· First Article Trial (FAT): Clients witness testing of the first production article to verify compliance with design and performance requirements before full-scale production.

WALKSON’s digitalized workflow, supported by MAGMASOFT for forging simulation and 3D printing for rapid prototyping, ensures precision and efficiency. Compliance with IATF 16949 and AS 9145 standards meets automotive and aerospace requirements.

Testing Procedures and Equipment

WALKSON conducts rigorous testing to ensure forged helical gears meet performance and quality standards, with protocols aligned to international guidelines. Clients are invited to witness tests, and third-party inspectors designated by clients are welcomed for independent oversight.

Specific Testing Protocols:

· Non-Destructive Testing (NDT):

· Standards: EN 10228-3, ASTM A275, ASTM E709.

· Tests:

· Ultrasonic Testing (UT): Detects internal defects like voids or inclusions.

· Magnetic Particle Testing (MT): Identifies surface and near-surface cracks.

· Radiographic Testing (RT): Verifies internal integrity for critical gears.

· Equipment: Ultrasonic flaw detectors, magnetic particle benches, X-ray machines.

· Frequency: 100% for critical components; sampling per ASTM E1444 for standard parts.

· Dimensional Inspection:

· Standards: DIN 3962, ISO 1328 (gear accuracy grades5–8).

· Tests: Measures tooth profile, helix angle, pitch, and runout using Zeiss CMM and Gleason GMM for precise gear metrology.

· Equipment: Zeiss CMM, Gleason GMM, 3D laser scanners.

· Tolerance: ±0.02 mm for critical dimensions.

· Mechanical Testing:

· Standards: ASTM E8, EN 10002-1.

· Tests:

· Tensile Testing: Verifies yield strength and elongation.

· Hardness Testing: Ensures surface/core hardness (200–350 HB per EN 10083).

· Impact Testing: Confirms toughness (Charpy V-notch).

· Equipment: Universal testing machines, Rockwell/Brinell hardness testers, Charpy impact testers.

· Performance Testing:

· Standards: ISO 6336, AGMA 2001.

· Tests: Load testing verifies torque capacity and fatigue life; noise/vibration analysis ensures smooth operation.

· Equipment: Gear test rigs, vibrometers.

· Conditions: Simulated loads up to 1.5x rated capacity.

· Process Capability Analysis:

· Standards: AIAG SPC Manual, ISO 21747.

· Tests: Statistical process control (SPC) ensures Cpk ≥ 1.33; measurement system analysis (MSA) validates inspection reliability.

· Equipment: SPC software, gauge R&R tools.

WALKSON’s testing facilities are ISO 17025-accredited, ensuring traceability and accuracy. Clients receive detailed reports, including dimensional layouts, material certificates, and NDT results, as part of PPAP submissions.

Advantages of Choosing WALKSON

Partnering with WALKSON for your forged helical gear needs offers unmatched benefits, ensuring quality, reliability, and cost-effectiveness:

· Global Expertise: Decades of experience supplying gears to mining, automotive, and energy sectors, with deep knowledge of international standards.

· Advanced Machining: Utilization of Gleason hobbing/shaping and Kapp Niles grinding ensures precision and performance.

· Rigorous Inspection: Zeiss CMM and Gleason GMM deliver industry-leading gear metrology for quality assurance.

· End-to-End Solutions: From design consultation to delivery, we streamline processes to reduce lead times and costs.

· Cutting-Edge Technology: Tools like MAGMASOFT, 3D printing, and 3D laser scanning ensure efficiency and accuracy.

· Stringent Quality Control: APQP, PPAP, PFMEA, and FAT protocols guarantee defect-free products, with full transparency for clients and third-party inspectors.

· Tailored Customization: Bespoke gear designs, helix angles, and materials, supported by rapid prototyping and reverse engineering.

· Competitive Pricing: Optimized processes deliver cost-effective solutions without compromising quality.

· Client-Centric Support: Prompt, personalized service via info@walkson.com (mailto:info@walkson.com) or WhatsApp/WeChat.

Contact WALKSON Today

Elevate your machinery’s performance with WALKSON’s precision-forged helical gears, designed for smooth, reliable operation. Our commitment to quality, innovation, and customer satisfaction makes us the preferred partner for global industries. Contact us at info@walkson.com (mailto:info@walkson.com) or via WhatsApp/WeChat to discuss your requirements, request a quote, or schedule a consultation. Choose WALKSON for world-class forged helical gears tailored to your success.

English

English  Deutsch

Deutsch  français

français  русский

русский  فارسی

فارسی  العربية

العربية  Español

Español  日本語

日本語  한국어

한국어  italiano

italiano  português

português  dansk

dansk  Suomi

Suomi