Advantages of Stainless Steel Sand Casting

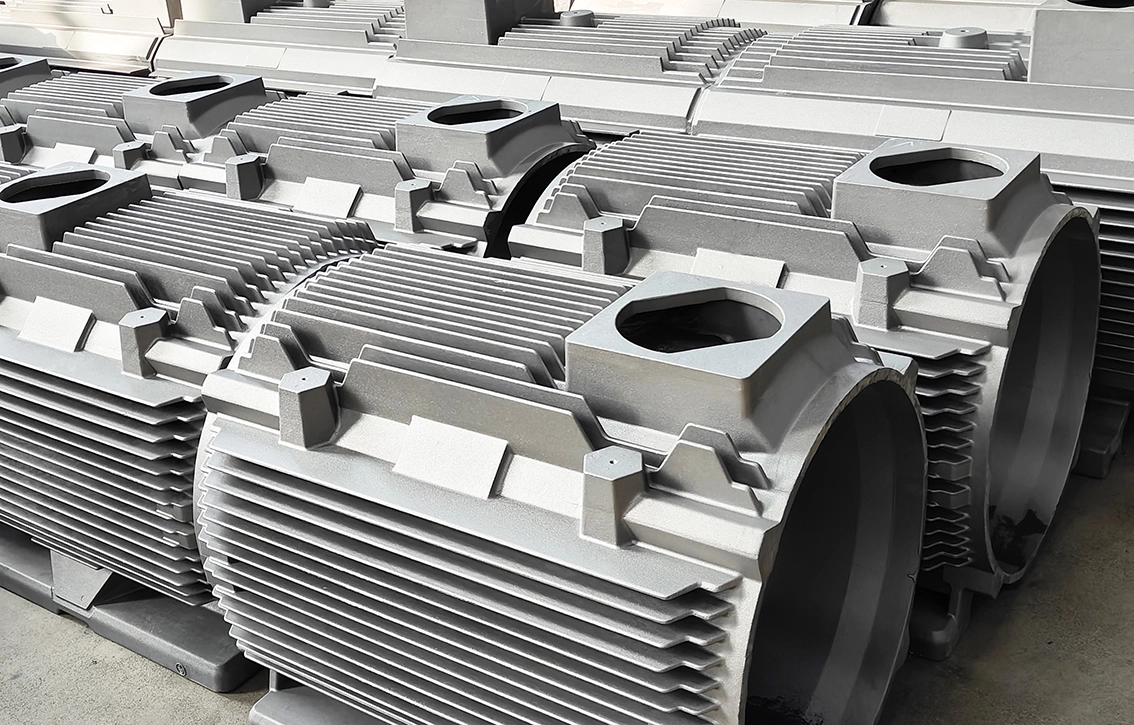

Complex Geometries: The sand casting process allows for the production of parts with complex shapes that would be difficult or impossible to achieve with other manufacturing methods.

Cost-Effectiveness: It is a relatively inexpensive process, especially for low to medium production runs, due to the simplicity of the materials and equipment required.

Material Versatility: Stainless steel, which is known for its excellent strength-to-weight ratio, corrosion resistance, and durability, is well-suited for use in harsh environments.

Customizable: Castings can be tailored to specific applications by selecting the appropriate alloy grade of stainless steel and adjusting the casting process.

Strong and Durable: Stainless steel castings offer high tensile strength, resistance to wear, and corrosion resistance, making them suitable for heavy-duty applications.

High Precision: The sand casting process can achieve good dimensional accuracy, reducing the need for excessive post-casting machining.

Applications of Stainless Steel Sand Castings

Stainless steel sand castings are used in various industries where strength, durability, and resistance to corrosion are critical. Below are some of the key industries and applications where stainless steel sand castings are commonly employed.

1. Aerospace Industry

The aerospace industry demands parts that are not only lightweight but also strong, durable, and capable of withstanding extreme environmental conditions. Stainless steel sand castings are used extensively in this sector to produce complex, high-performance components.

Turbine Blades and Housings: Stainless steel sand casting is used to manufacture turbine blades, stators, and casings for aircraft engines due to its high-temperature resistance and strength.

Structural Components: Engine mounts, brackets, and support structures made from stainless steel provide strength and durability while maintaining the necessary weight requirements for aircraft.

Aircraft Fittings: Clamps, fasteners, and other hardware components made from stainless steel sand casting offer corrosion resistance and the necessary strength for flight applications.

Benefits in Aerospace:

High Temperature Resistance: Stainless steel can handle extreme temperatures, making it ideal for engine parts and other high-stress components.

Corrosion Resistance: Protects against corrosion from exposure to environmental elements, including moisture and salt.

Strength and Durability: Stainless steel castings are strong and durable, which is essential for aerospace applications that must endure high mechanical and thermal stresses.

2. Chemical and Petrochemical Industry

In the chemical and petrochemical industries, stainless steel sand castings are crucial for producing equipment that can withstand harsh chemical environments, extreme temperatures, and high-pressure conditions.

Valve Bodies: Gate valves, ball valves, and check valves used in pipelines and chemical reactors are commonly made using stainless steel sand casting.

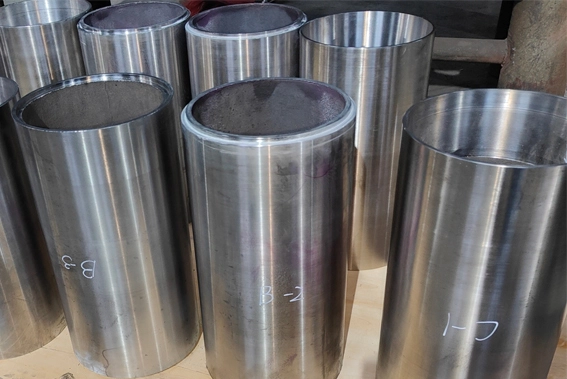

Pumps: Pump housings, impellers, and shafts are cast from stainless steel to handle aggressive chemicals and prevent rust or degradation.

Flanges and Fittings: Stainless steel flanges, manifolds, and couplings are cast to withstand the pressure and corrosive nature of chemicals being processed.

Benefits in Chemical and Petrochemical:

Corrosion Resistance: Stainless steel’s ability to resist corrosion makes it ideal for the harsh chemical environments common in petrochemical and chemical industries.

Strength: Stainless steel parts can endure high pressures and mechanical forces without compromising integrity.

Long Service Life: The durability of stainless steel allows for long-lasting, reliable components in critical systems.

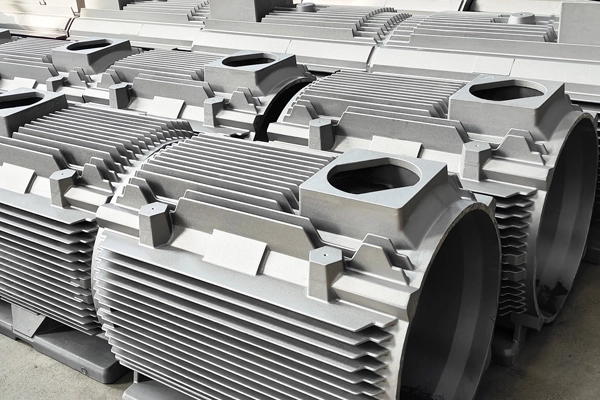

3. Food Processing Industry

The food processing industry relies on stainless steel for its combination of strength, ease of cleaning, and resistance to corrosion. Stainless steel sand castings are used to produce equipment that handles both the mechanical stresses and the sanitary requirements of food production.

Processing Equipment: Hoppers, mixing blades, and chutes used in food production lines are commonly made from stainless steel castings.

Housings: Motor housings, bearings, and pump housings are often cast in stainless steel for food processing machinery to maintain hygiene and ensure durability.

Food Contact Parts: Conveyors, fittings, and valves used in food and beverage plants need to be cast in stainless steel for its non-reactive nature and corrosion resistance.

Benefits in Food Processing:

Hygienic: Stainless steel’s non-porous surface is easy to clean, making it ideal for food contact applications.

Corrosion Resistance: Ensures long-lasting performance in environments exposed to moisture, acids, and other corrosive substances.

Strength and Durability: Stainless steel castings are strong enough to handle the mechanical demands of food processing equipment.

4. Marine Industry

The marine industry, which involves exposure to seawater, salt, and harsh weather conditions, heavily relies on stainless steel sand castings for producing parts that need to resist corrosion while maintaining strength and durability.

Propellers: Stainless steel is often used for casting marine propellers due to its strength and resistance to corrosion from seawater.

Rudders and Shafts: Rudder blades, stern shafts, and propeller shafts made from stainless steel provide the required mechanical strength and corrosion resistance.

Marine Hardware: Deck fittings, anchors, and marine valves are commonly made from stainless steel for their durability and resistance to the harsh marine environment.

Benefits in Marine:

Corrosion Resistance: Stainless steel is ideal for parts exposed to seawater due to its high resistance to saltwater corrosion.

Strength: The material can endure the harsh marine environment while withstanding high mechanical stresses.

Long-Term Durability: Stainless steel’s resistance to wear and fatigue extends the service life of marine equipment.

5. Power Generation and Energy Industry

In power generation and energy sectors, stainless steel sand castings are used to produce components that must withstand extreme temperatures, high pressures, and corrosive environments, especially in power plants and renewable energy applications.

Turbine Components: Stainless steel is used to cast blades, rotors, and casing parts for gas turbines, steam turbines, and wind turbines due to its heat resistance and strength.

Pressure Vessels: Boiler components, pipes, valves, and flanges are critical in power generation systems and are commonly made using stainless steel sand casting to withstand high pressure and temperature.

Nuclear Plant Components: Stainless steel is often used for components in nuclear reactors, such as coolant pumps, control rods, and pressure vessels due to its resistance to radiation and high-temperature environments.

Benefits in Power Generation:

High Temperature and Pressure Resistance: Stainless steel withstands extreme conditions found in power generation systems, including high heat and mechanical stress.

Corrosion Resistance: Stainless steel protects parts from corrosion in environments that expose components to aggressive fluids and gases.

Durability: The robustness and longevity of stainless steel ensure that power plant components last for many years under demanding operating conditions.

6. Heavy Equipment and Mining Industry

The heavy equipment and mining industry uses stainless steel sand castings to produce parts that can handle the mechanical stresses, wear, and corrosion associated with mining, excavation, and construction work.

Crusher Parts: Crusher jaws, mantles, and cones used in mineral processing and heavy-duty crushing operations are made from stainless steel to provide wear resistance and durability.

Excavator Components: Bucket teeth, brackets, and frames are commonly cast in stainless steel for use in excavators, bulldozers, and mining equipment.

Conveyor Systems: Stainless steel castings are used for conveyor pulleys, bearings, and rollers in heavy-duty mining and material handling equipment.

Benefits in Heavy Equipment and Mining:

Wear Resistance: Stainless steel’s hardness and resistance to abrasion make it ideal for components that undergo heavy wear in mining and excavation.

Corrosion Resistance: Stainless steel protects components from corrosion caused by exposure to moisture, chemicals, and abrasive materials.

Strength: Stainless steel castings are strong enough to withstand the heavy loads and mechanical forces in mining and heavy equipment applications.

Conclusion

Stainless steel sand castings offer a versatile, cost-effective solution for producing high-strength, durable, and corrosion-resistant components used across a variety of industries. Whether it is in aerospace, automotive, chemical processing, food production, marine, or heavy equipment, stainless steel’s inherent properties make it an ideal material for applications that require strength, durability, and resistance to harsh environments with the ability to create complex geometries and precise parts.

English

English  Deutsch

Deutsch  français

français  русский

русский  فارسی

فارسی  العربية

العربية  Español

Español  日本語

日本語  한국어

한국어  italiano

italiano  português

português  dansk

dansk  Suomi

Suomi