M/Whatsapp: +86-188 6716 5932 ( Sales 1)

-

Services

- Forging

-

(Metal) Sand Casting

- Stainless Steel Sand Casting

- Iron Sand Casting

- ADI Castings

- Copper Sand Casting

- Ductile Iron Sand Castings

- White Iron Sand Castings

- Resin Sand Casting

- Steel Sand Casting

- Vacuum Lost Foam Casting

- Furan Sand Casting

- Water Glass Sand Casting

- Vacuum Sand Casting

- Gravity Sand Casting

- Aluminum Sand Casting

- Brass Sand Casting

- Heat Treatment

- CNC Machining

- Steel Fabrication

- Hardfacing

-

Custom Parts

- Forged Gears

-

Metal Recycling Parts

- Low Alloy Casting Steel Cap for Metal Shredders

- Hi Manganese Steel Liners

- Forged Shredder Rotor Shafts

- Low Alloy DHT Hammer

- Low Alloy Cast Iron Anvils

- Wear Plates (High Chromium Cast Iron)

- Rotor Disks (Forged Alloy Steel)

- Hammer Axles (Forged Steel)

- Gratings (Austenitic Manganese Steel, ASTM A128 Grade B)

- Seamless Forged Rings (Low Alloy Steel)

- Forged Train Wheels

-

Centrifugal Casting Parts

- Centrifugal Casting Pipes for Reformer Heaters

- Centrifugal Cast Bends for Industrial Heating Systems

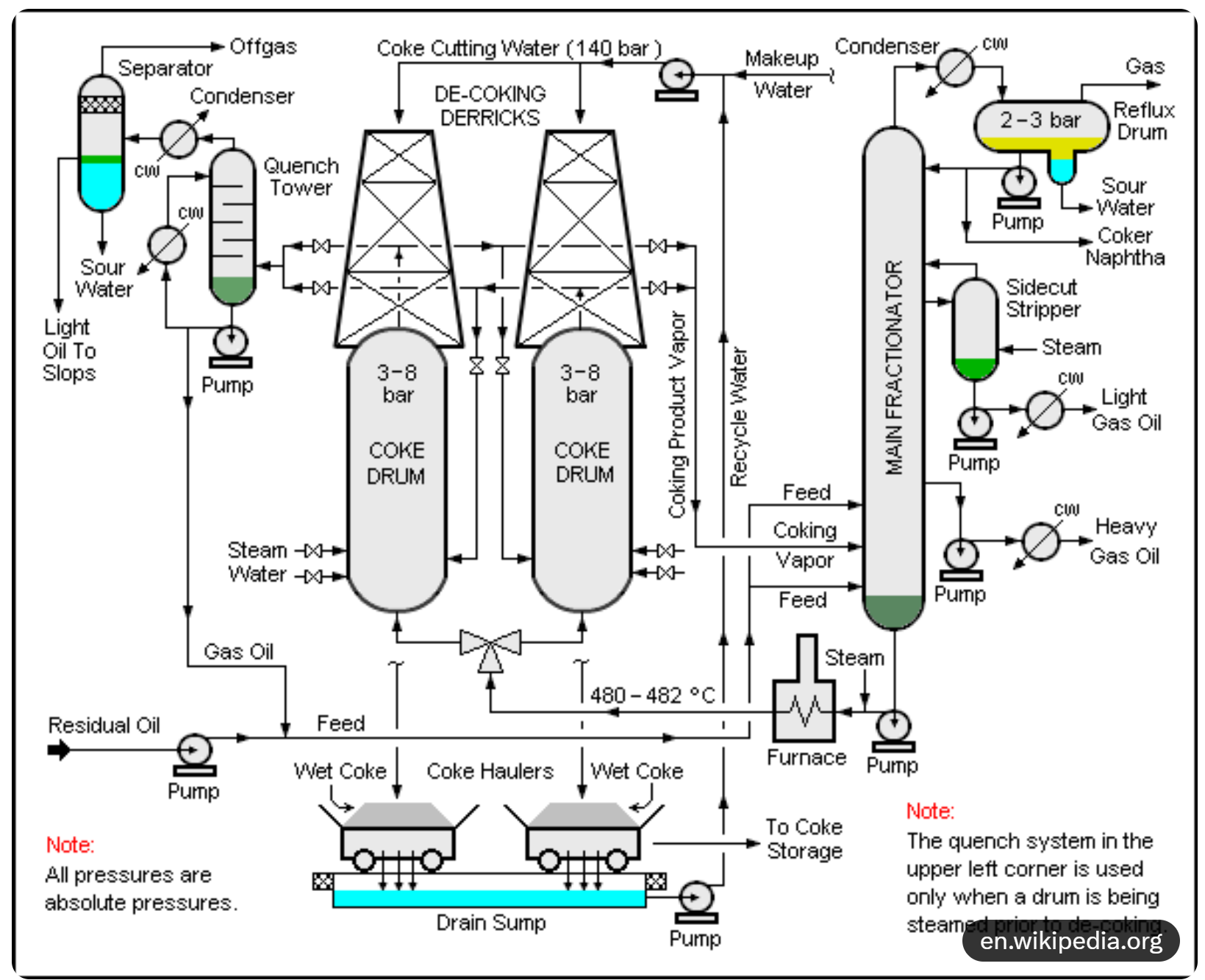

- High-Performance Manifolds for Delayed Coking Heaters

- Centrifugal Cast Tubes for Reactor Charge Heaters

- Custom-Cast Convection Modules for Continuous Reforming Heaters

- Air Pre-Heater Tubes Made from Centrifugal Casting

- Centrifugal Cast Pipe Fittings for High-Pressure Systems

- Centrifugal Cast Alloy Pipes for High-Corrosion Environments

- Customized High-Temperature Alloy Bends for Industrial Use

- Centrifugal Cast Pipe Joints for Heavy Industrial Equipment

- High-Nickel Alloy Centrifugal Casting Pipes for Chemical Plants

- Precision Centrifugal Cast Pipes for Oil Refining Applications

- Centrifugal Cast Heat Exchanger Tubes for Petrochemical Industries

- High-Strength Centrifugal Casting Components for Power Plants

- 15 Centrifugal Cast Fittings for Vacuum Pressure Fire Heaters

- Forged Planetary Gear System Parts

- Roots Blower Casting Parts

- Cast White Iron Liners

- Ground Engaging Tools

- Bucket Wear Products

- Undercarriage System

English

English  Deutsch

Deutsch  français

français  русский

русский  فارسی

فارسی  العربية

العربية  Español

Español  日本語

日本語  한국어

한국어  italiano

italiano  português

português  dansk

dansk  Suomi

Suomi