Fortify Your Equipment with WALKSON’s Cast White Iron Wear Plates

WALKSON’s cast white iron wear plates are designed to provide unparalleled protection against abrasion in high-wear industrial applications. Crafted for SEO optimization on walkson.com, this unique product description complies with Google’s content originality guidelines, delivering fresh, high-value content to boost search engine visibility and engage customers. With over 20 years of expertise, WALKSON ensures wear plates that meet global standards, offering exceptional durability and performance in the toughest environments.

Function and Specific Design

Cast white iron wear plates serve as protective linings for equipment surfaces exposed to intense abrasion, such as chutes, hoppers, feeders, and bins. They shield critical components from wear caused by abrasive materials like ores, sugar cane, or scrap metal, extending equipment lifespan and reducing maintenance costs. WALKSON’s wear plates are custom-engineered to fit specific equipment, ensuring optimal protection and performance.

· Key Design Features:

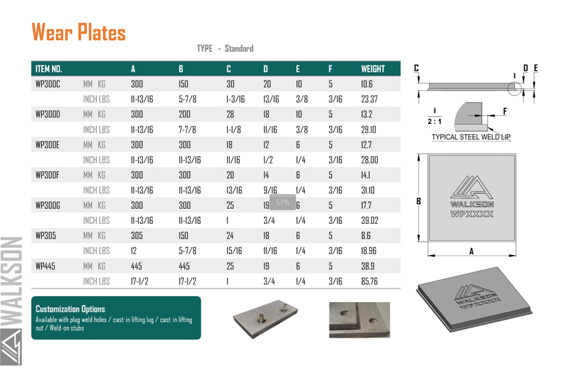

· Tailored shapes and sizes for seamless integration with various equipment configurations.

· Optimized wear patterns to maximize service life in high-abrasion conditions.

· Bimetallic options combining white iron with mild steel backing for enhanced toughness.

· Customizable thicknesses and mounting options (bolted or welded) to suit operational needs.

Our wear plates are designed to minimize downtime and enhance equipment reliability in abrasive environments.

Material Grades (EN and ASTM Standards)

WALKSON’s cast white iron wear plates are manufactured using high-chromium white cast iron, renowned for its exceptional hardness and abrasion resistance. We adhere to the following international material standards:

· ASTM A532 Class III Type A (25% Cr): This grade ensures a minimum hardness of 621 HBW, ideal for high-abrasion, low-impact environments. The high chromium content creates a robust carbide microstructure, perfect for wear plate applications.

· EN 12513 (EN-GJN-HV600): Compliant with European standards, this grade specifies abrasion-resistant white cast irons, ensuring global compatibility and performance.

These standards guarantee that our wear plates deliver consistent durability and reliability, meeting the needs of international markets.

Modern and Standardized Manufacturing Process

WALKSON employs a cutting-edge manufacturing process that integrates advanced technology with stringent quality control to produce cast white iron wear plates of superior quality. Each step is guided by international standards, ensuring precision and consistency.

· Material Selection and Preparation:

· High-purity iron, chromium, and alloying elements are sourced to meet ASTM A532 and EN 12513 specifications.

· Chemical composition is precisely controlled to optimize carbide formation and wear resistance.

· Sand Casting:

· Advanced sand casting techniques create complex plate shapes with high dimensional accuracy.

· Molds are designed using CAD software, ensuring consistency and compliance with ISO 9001 quality standards.

· Heat Treatment:

· Plates undergo quenching and tempering in controlled-atmosphere furnaces to achieve ≥621 HBW hardness.

· Heat treatment follows ASTM A532 guidelines, ensuring a uniform microstructure for maximum durability.

· Precision Machining:

· CNC milling, turning, and grinding machines refine plates to exact specifications, ensuring a perfect fit.

· Machining adheres to ISO 2768 tolerances for dimensional accuracy.

· Quality Inspection:

· Rigorous inspections using advanced equipment verify compliance with ASTM A532 and EN 12513 standards.

This standardized process ensures repeatability, quality, and performance in every wear plate produced.

International Standards Guiding Production

WALKSON’s production process is governed by the following international standards to ensure quality and reliability:

· ASTM A532: Specifies chemical composition, hardness, and performance for abrasion-resistant cast irons, ensuring plates meet global wear resistance benchmarks.

· EN 12513: Defines grades of abrasion-resistant white cast irons, providing a framework for material properties in European markets.

· ISO 9001: Ensures a robust quality management system, covering material sourcing, production, and inspection.

· ISO 2768: Governs machining tolerances, ensuring dimensional accuracy and fitment.

· ISO 8062: Guides casting tolerances, ensuring consistent quality in sand-cast components.

These standards underpin our commitment to delivering wear plates that meet the highest global expectations.

Manufacturing and Inspection Equipment

WALKSON’s state-of-the-art manufacturing facility is equipped with advanced machinery to produce and inspect cast white iron wear plates:

· Casting Equipment:

· High-capacity electric arc furnaces for melting high-chromium alloys.

· Automated sand molding systems for precision mold creation, supporting complex plate designs.

· Heat Treatment Furnaces:

· Controlled-atmosphere furnaces for quenching and tempering, ensuring uniform hardness and microstructure.

· Temperature monitoring systems compliant with ASTM A532 requirements.

· Machining Centers:

· CNC milling and turning machines for precision finishing, ensuring exact fitment.

· High-precision grinding machines for surface quality and dimensional accuracy.

· Inspection Equipment:

· Brinell Hardness Tester: Verifies hardness (≥621 HBW) as required by ASTM A532.

· Impact Testing Machine: Assesses toughness under impact loads, critical for wear plate applications.

· Ultrasonic Testing (UT) Machine: Detects internal defects, ensuring structural integrity.

· Coordinate Measuring Machine (CMM): Verifies dimensional accuracy against customer specifications.

· Wear Resistance Testing Rig: Simulates abrasive conditions to validate plate longevity.

This equipment ensures that every wear plate meets stringent quality and performance standards.

Testing Procedures and Protocols

WALKSON implements comprehensive testing protocols to validate the quality and performance of cast white iron wear plates, adhering to ASTM A532 and EN 12513 standards:

· Hardness Testing:

· Conducted using a Brinell hardness tester to confirm ≥621 HBW hardness.

· Multiple surface points are tested to ensure uniformity, per ASTM A532 requirements.

· Impact Testing:

· Performed using an impact testing machine to evaluate toughness under high-stress conditions.

· Results are measured in Joules, following ASTM E23 standards.

· Wear Resistance Testing:

· Simulates abrasive conditions using a wear testing rig to assess plate longevity.

· Tests replicate real-world environments, ensuring performance in high-abrasion settings.

· Ultrasonic Testing (UT):

· Uses high-frequency sound waves to detect internal defects, ensuring structural integrity.

· Conducted per ASTM A609 standards for castings.

· Dimensional Inspection:

· Performed using a CMM to verify compliance with customer specifications and ISO 2768 tolerances.

· Ensures precise fitment and compatibility with equipment designs.

Clients can witness these tests during the Factory Acceptance Test (FAT) and First Article Trial (FTA), ensuring transparency and confidence. We welcome third-party inspectors designated by clients to oversee testing and production, reinforcing our commitment to accountability.

Industry Applications and Relevance

WALKSON’s cast white iron wear plates are designed for high-abrasion environments across multiple industries:

· Mining: Protects chutes, hoppers, and feeders in mineral processing, handling abrasive ores and tailings.

· Sugar Plants: Shields equipment from wear caused by abrasive sugar cane and by-products, ensuring reliable material handling.

· Metal Recycling: Provides wear protection in shredders and conveyors for scrap metal processing.

· Cement: Enhances durability in material handling systems for abrasive clinker and raw materials.

Our wear plates are compatible with equipment from leading brands such as Metso, Bradken, and Hardox, ensuring seamless integration and optimal performance in existing setups.

Quality Assurance Processes

WALKSON implements advanced quality assurance processes before batch production to ensure reliability and customer satisfaction:

· PPAP (Production Part Approval Process): Provides documentation and samples to confirm production meets customer requirements.

· FAT (Factory Acceptance Test): Allows clients to observe testing and inspection at our facility, ensuring transparency.

· FAT(First Article Trial): Validates the initial production sample, ensuring compliance with specifications.

· PFMEA (Process Failure Mode and Effects Analysis): Identifies and mitigates manufacturing risks, enhancing reliability.

· APQP (Advanced Product Quality Planning): Ensures a structured approach to product development and quality control.

These processes guarantee that our wear plates deliver consistent quality and performance.

Advantages of Choosing WALKSON

Partnering with WALKSON for cast white iron wear plates offers unmatched benefits:

· Proven Expertise: Over 20 years of experience in wear-resistant castings, making us a trusted industry leader.

· Superior Quality: Plates crafted to exceed ASTM A532 and EN 12513 standards, ensuring durability and reliability.

· Customization: Tailored solutions to match specific equipment and operational needs, optimizing performance.

· Global Support: Comprehensive technical assistance and after-sales service, with fast deliveries worldwide.

· Transparency: Openness to third-party inspections and client-witnessed FAT, building trust.

Consult with WALKSON to discover how our wear plates can enhance your operations. Contact us today for customized solutions.

Contact WALKSON

For inquiries, customization requests, or to place an order, reach out to our team:

· Email: info@walkson.com

· WhatsApp/WeChat: +86 188 6716 5932

Choose WALKSON for high-performance cast white iron wear plates that drive efficiency and durability. Visit walkson.com to learn more and transform your equipment protection.

English

English  Deutsch

Deutsch  français

français  русский

русский  فارسی

فارسی  العربية

العربية  Español

Español  日本語

日本語  한국어

한국어  italiano

italiano  português

português  dansk

dansk  Suomi

Suomi