Top 10 Casting and Forging Parts for Metal Recycling Shredders

Below are the top 10 casting and forging parts commonly used in metal recycling shredders, along with their functions and material specifications:

1. High Manganese Dual Hardness Steel Liners (Mn13Cr2, Mn18Cr2)

Function: Protect shredder and crusher chambers from abrasive wear and high-impact forces, preserving structural integrity.

Material: Mn13Cr2 (13% manganese with chromium) for standard applications; Mn18Cr2 (18% manganese with chromium) for extreme conditions, offering a ductile core (~20–25 HRC) and work-hardened surface (up to 50–55 HRC).

Benefit: Work-hardening surface extends service life under repetitive impacts.

2. Low Alloy Casting Steel Caps (42CrMo4)

Function: Shield rotor assemblies from wear and impact, acting as sacrificial components in shredders.

Material: 42CrMo4, hardened to 42–44 HRC post-Q&T for balanced strength and toughness.

Benefit: Enhances rotor lifespan, reducing maintenance costs.

3. Forged Shredder Rotor Shafts (42CrMo4)

Function: Transmit torque to the rotor assembly, enabling efficient shredding of scrap metal.

Material: 42CrMo4, hardened to 42–44 HRC for high tensile strength and fatigue resistance.

Benefit: Forged grain structure ensures durability under high-torque loads.

4. High Manganese Steel Hammers (Mn13Cr2, Mn18Cr2)

Function: Crush scrap metal in shredders through high-impact action.

Material: Mn13Cr2 or Mn18Cr2, work-hardening to 50–55 HRC under impact.

Benefit: Exceptional toughness and wear resistance for prolonged hammer life.

5. Low Alloy Cast Iron Anvils

Function: Stationary components that withstand hammer impacts during shredding.

Material: Low alloy cast iron, hardened for high compressive strength and abrasion resistance.

Benefit: Maintains structural integrity under repetitive impacts.

6. Wear Plates (High Chromium Cast Iron)

Function: Protect shredder housings and balers from abrasive wear.

Material: High chromium cast iron, achieving up to 60 HRC for extreme wear resistance.

Benefit: Reduces housing damage, extending equipment lifespan.

7. Rotor Disks (Forged 42CrMo4)

Function: Mount hammers and support rotor assemblies in shredders.

Material: Forged 42CrMo4, hardened to 42–44 HRC for structural integrity.

Benefit: High strength and resistance to bending/torsion stresses.

8. Hammer Axles (Forged 42CrMo4)

Function: Secure hammers to rotors, enduring high shear forces.

Material: Forged 42CrMo4, hardened to 42–44 HRC for shear strength.

Benefit: Ensures reliable hammer attachment under dynamic loads.

9. Gratings (Austenitic Manganese Steel, ASTM A128 Grade B)

Function: Control output size of shredded scrap by acting as screens in shredders.

Material: ASTM A128 Grade B (similar to Mn13Cr2), work-hardening to 50–55 HRC.

Benefit: High toughness and wear resistance for consistent output.

10. Seamless Forged Rings (42CrMo4)

Function: Structural components in balers and shears for load-bearing applications.

Material: Forged 42CrMo4, hardened to 42–44 HRC for fatigue resistance.

Benefit: Uniform grain structure enhances durability in high-pressure systems.

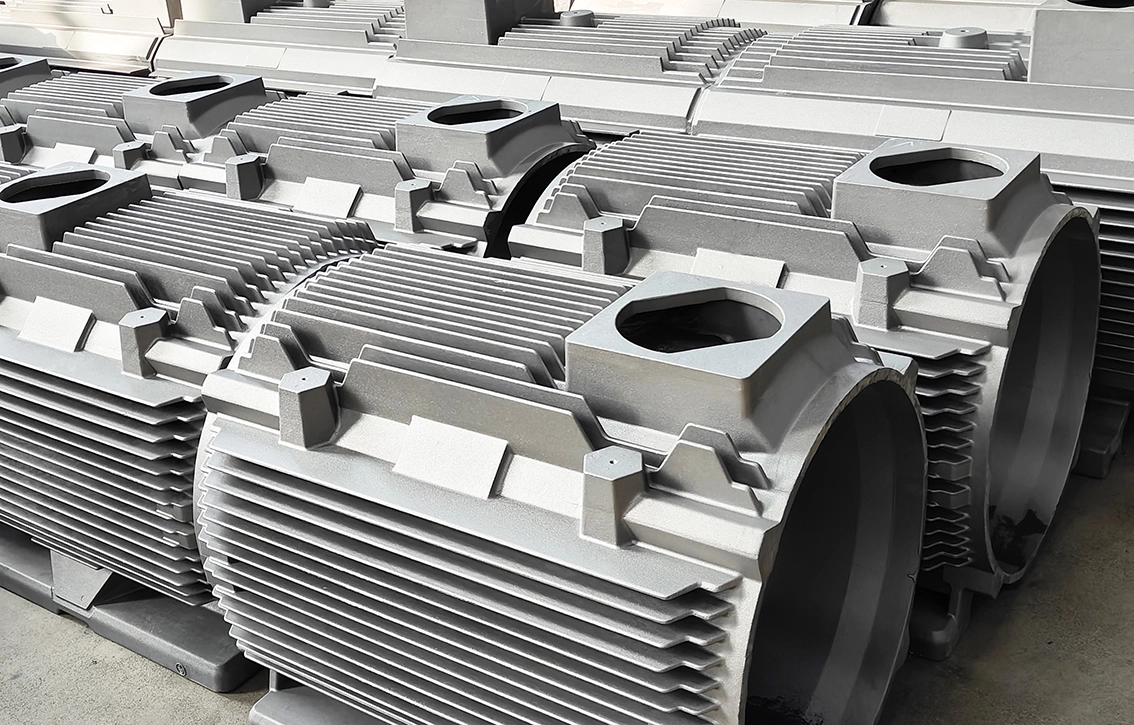

Modern and Standardized Manufacturing Process

WALKSON employs a state-of-the-art manufacturing process for metal recycling parts, guided by international standards and advanced quality planning methodologies like APQP to ensure reliability, consistency, and performance. Our processes adhere to standards such as ISO 9001:2015, ASTM A128/A128M (for manganese steel castings), EN 10083-3 (for 42CrMo4), and ASTM A788/A788M (for forgings), with additional quality control measures to meet client expectations.

Advanced Product Quality Planning (APQP):

Initiated to define quality objectives, design specifications, and production processes for castings and forgings.

Involves cross-functional teams to align with client requirements and industry standards.

Ensures traceability and compliance with ISO/TS 16949 for industrial components.

Outputs include process flow charts, control plans, and risk assessments, setting the foundation for PFMEA.

Process Failure Mode and Effects Analysis (PFMEA):

Conducted during APQP to identify potential failure modes (e.g., casting porosity, forging cracks, dimensional inaccuracies).

Risks are prioritized using Risk Priority Numbers (RPN) and mitigated through corrective actions, such as optimized mold design or forging parameters.

PFMEA ensures robust process reliability, aligning with AIAG guidelines.

Material Selection:

High-quality materials (Mn13Cr2, Mn18Cr2, 42CrMo4, high chromium cast iron) are sourced per ASTM A128/A128M, EN 10083-3, and ASTM A29/A29M.

Spectrographic analysis verifies alloy content (e.g., manganese, chromium, molybdenum).

Casting (for Liners, Caps, Hammers, Anvils, Wear Plates, Gratings):

Sand molds are prepared using automated molding systems, complying with ISO 8062 (Dimensional Tolerances).

Molten metal is poured in electric arc furnaces (EAF) or induction furnaces, adhering to ASTM E781 (Evaluating Absorptive Materials in Castings).

Forging (for Shafts, Rotor Disks, Hammer Axles, Rings):

Heat Treatment:

Castings (e.g., manganese steel liners) undergo solution annealing and water quenching per ASTM A128/A128M.

Forgings (e.g., 42CrMo4 shafts) are quenched and tempered to 42–44 HRC per EN 10083-3 and ASTM A370.

Heat treatment is monitored using automated furnaces, complying with AMS 2750 (Pyrometry Standards).

Machining and Finishing:

Components are machined using CNC lathes, milling, and grinding equipment, meeting ISO 2768 (General Tolerances).

Surface treatments (e.g., shot blasting, polishing, coatings) enhance durability and appearance.

First Article Trial (FAT):

A First Article Trial produces and evaluates a sample component (e.g., liner, shaft) to ensure it meets design and performance specifications, including hardness (42–44 HRC for 42CrMo4, 50–55 HRC work-hardened for manganese steel).

FAT includes comprehensive testing and dimensional verification, with results documented in a First Article Inspection Report (FAIR).

Clients or third-party inspectors may witness FAT before full-scale production.

Production Part Approval Process (PPAP):

Validates production processes before batch manufacturing, incorporating FAT results and ensuring compliance with client specifications.

PPAP documentation includes material certifications, dimensional reports, control plans, PFMEA results, and FAIR, submitted for client approval per AIAG PPAP requirements.

Quality Control:

Each part undergoes rigorous inspection (see Testing Procedures below) to ensure defect-free performance.

Quality controls are defined during APQP and monitored through PFMEA, with PPAP ensuring process validation.

Equipment Involved:

Casting: Electric arc furnaces, induction furnaces, automated sand molding systems, resin-bonded sand mixers.

Forging: Hydraulic presses, drop hammers.

Machining: CNC machining centers, lathes, milling machines, grinding equipment.

Heat Treatment: Automated annealing, quenching, and tempering furnaces.

Inspection: Ultrasonic testing (UT) machines, magnetic particle testing (MT) equipment, dye penetrant testing (PT) systems, coordinate measuring machines (CMM).

International Standards Guiding Production

WALKSON's manufacturing process complies with globally recognized standards to ensure product reliability and traceability:

ISO 9001:2015: Quality management system for consistent production.

ASTM A128/A128M: Austenitic manganese steel castings (Mn13Cr2, Mn18Cr2).

EN 10083-3: Quenched and tempered steels (42CrMo4).

ASTM A788/A788M: General requirements for steel forgings.

EN 10250-2: Open die steel forgings.

ASTM A370: Mechanical testing of steel products.

ISO 8062: Dimensional tolerances for castings.

ASTM E781: Evaluation of casting quality.

AMS 2750: Heat treatment pyrometry standards.

ISO 2768: General tolerances for machined components.

ISO/TS 16949: Quality management for industrial components (APQP, PPAP, FAT).

AIAG Guidelines: For PFMEA, PPAP, and FAT processes.

Testing Procedures and Protocols

To ensure the integrity of our metal recycling parts, WALKSON implements comprehensive testing protocols in accordance with international standards, integrated with APQP, PFMEA, FAT, and PPAP requirements. Testing verifies material properties (e.g., 42–44 HRC for 42CrMo4, 50–55 HRC work-hardened for manganese steel) and performance. Clients are invited to witness these tests, including the First Article Trial, and third-party inspectors (e.g., SGS, Bureau Veritas, or client-designated agencies) are welcomed to oversee the process, ensuring transparency and confidence in our products.

Non-Destructive Testing (NDT):

Ultrasonic Testing (UT): Performed per ASTM A609 (castings) or ASTM A388 (forgings) to detect internal flaws like voids or inclusions.

Magnetic Particle Testing (MT): Conducted per ASTM E709 to identify surface and near-surface defects (applicable for non-austenitic components).

Dye Penetrant Testing (PT): Applied per ASTM E165 to detect surface cracks or porosity.

Dimensional Inspection:

Conducted using coordinate measuring machines (CMM) and precision gauges to verify compliance with ISO 8062 (castings) or ISO 2768 (forgings).

Gauging inspection ensures compatibility with shredder systems, documented in PPAP and FAT reports.

Mechanical Testing:

Hardness Testing: Performed per ASTM E10 (Brinell) or ASTM E18 (Rockwell) to confirm hardness (42–44 HRC for 42CrMo4; 20–25 HRC core, 50–55 HRC work-hardened for manganese steel).

Tensile Testing: Conducted per ASTM A370 to verify yield strength, tensile strength, and elongation.

Impact Testing: Performed per ASTM E23 (Charpy V-Notch) to assess toughness.

Chemical Composition Analysis:

Visual Inspection:

First Article Trial (FAT) Testing:

Produces a sample component (e.g., liner, shaft, hammer) and subjects it to all applicable tests (UT, PT, MT, dimensional, mechanical, chemical), verifying hardness and performance.

FAT ensures production processes meet specifications, with results documented in a First Article Inspection Report (FAIR) for PPAP submission.

Client Oversight:

Clients may schedule on-site visits to witness UT, PT, MT, gauging inspections, and FAT at WALKSON’s facilities.

Third-party inspectors are welcomed to verify compliance with standards, FAT results, and PPAP requirements.

Comprehensive test reports, FAIR, PPAP documentation, and certificates of conformity are provided for traceability.

Advantages of Choosing WALKSON

Uncompromising Quality: Our metal recycling parts, including Mn13Cr2/Mn18Cr2 liners and 42CrMo4 shafts, are manufactured with APQP, PFMEA, PPAP, and FAT, ensuring defect-free performance and compliance with global standards.

Comprehensive Range: Offers a full suite of castings and forgings tailored for shredder applications, from liners to shafts.

Customization: Tailored solutions to match specific shredder models and operational needs, validated through FAT and PPAP.

Global Compatibility: Designed for seamless integration with LINDEMANN, Metso, Shred-Tech, and other leading shredders.

Transparent Quality Assurance: Client and third-party oversight of testing and FAT, backed by detailed PPAP documentation and FAIR, ensures confidence in product integrity.

Risk Mitigation: PFMEA identifies and eliminates potential failure modes, delivering reliable components.

Expert Support: Our team of engineers and metallurgists provides technical consultation to optimize component performance.

Competitive Pricing: High-quality products at cost-effective prices, delivering value to your operations.

Reliable Supply Chain: Global logistics network ensures timely delivery to clients in the EU, USA, Australia, and beyond.

Call-to-Action

Elevate your metal recycling operations with WALKSON's premium metal recycling parts, crafted from Mn13Cr2, Mn18Cr2, and 42CrMo4, backed by APQP, PFMEA, PPAP, and First Article Trial for unmatched quality. Contact us today for custom solutions, detailed specifications, or to schedule a consultation. Email us at info@walkson.com or reach out via WhatsApp/WeChat for prompt assistance. Request a quote now and experience the WALKSONdifference!

English

English  Deutsch

Deutsch  français

français  русский

русский  فارسی

فارسی  العربية

العربية  Español

Español  日本語

日本語  한국어

한국어  italiano

italiano  português

português  dansk

dansk  Suomi

Suomi