In screw rotor manufacturing for air compressors, refrigeration systems, and Roots blowers, even the smallest deviation can cause massive efficiency losses, increased wear, and premature failure. Precision isn't just a feature — it's the difference between good and world-class performance.At WALKSON, we specialize in forging and finishing high-performance screw rotors that leading compressor brands trust worldwide. One of the key machines enabling us to consistently hit micron-level accuracy is the Holroyd HG500 Helical Profile Grinder — arguably the most advanced helical grinding platform available today.Why Precision Matters in Screw Rotor ManufacturingScrew rotors operate with extremely tight clearances (often <0.05 mm). Any profile error leads to leakage, reduced volumetric efficiency, and higher energy consumption.The helical geometry is complex. Traditional grinding methods struggle to maintain consistent root-to-tip accuracy across long rotors while controlling surface finish and avoiding thermal damage.This is where the HG500 excels.The Holroyd HG500: Built for Next-Level PrecisionLaunched in 2025 by PTG Holroyd Precision, the HG500 was specifically engineered to solve the challenges of modern large-capacity rotor production.Here's how it delivers unmatched precision:Siemens SINUMERIK ONE CNC + Holroyd Profile Management System (HPMS)

The combination of Siemens'digitally native control and Holroyd's proprietary HPMS software allows mathematical perfection of the helical profile. Digital twin simulation before grinding eliminates trial-and-error and guarantees first-part-correct results.

Extreme Rigidity and Thermal Stability

The machine's polymer concrete base and temperature-controlled coolant system keep thermal growth to an absolute minimum — critical when grinding rotors up to 510 mm diameter and 1,500 kg.

Dual Grinding Technology Options

Choose dressable vitrified aluminium oxide wheels for maximum flexibility or plated CBN for ultra-high stock removal with minimal dressing. In either mode, surface finishes better than Ra 0.4 μm are standard.

On-Machine Profile Inspection and Automatic Correction

Integrated probing and HPMS closed-loop correction ensure every rotor meets or exceeds drawing tolerances — even on the most demanding “N” or “G” profiles used in oil-free compressors.

Single Setup Roughing and Finishing

By performing both roughing and finishing in one clamping, the HG500 eliminates cumulative setup errors that plague conventional multi-machine processes.

The result? Rotors with profile accuracy routinely within ±0.005 mm and lead error <0.008 mm/m — numbers that directly translate to 3–5% efficiency gains for our customers.Real-World Impact at WALKSONAt WALKSONWe forge screw rotors up to 580 mm diameter using closed-die and open-die techniques, then finish them on state-of-the-art grinding platforms including the Holroyd HG500.

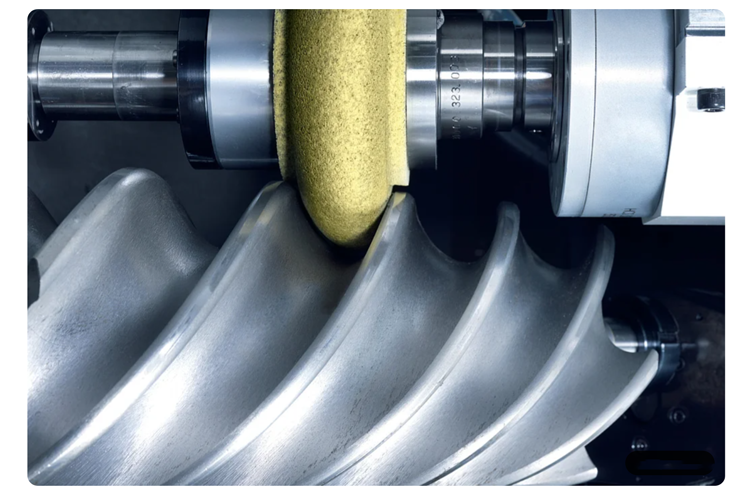

The Holroyd HG500 in action at full capacity – precision grinding a large helical rotor

This machine has transformed our ability to deliver forged rotors that outperform cast alternatives in both strength and precision. Customers regularly report extended service life and lower operating noise — benefits that come directly from the HG500's capabilities.

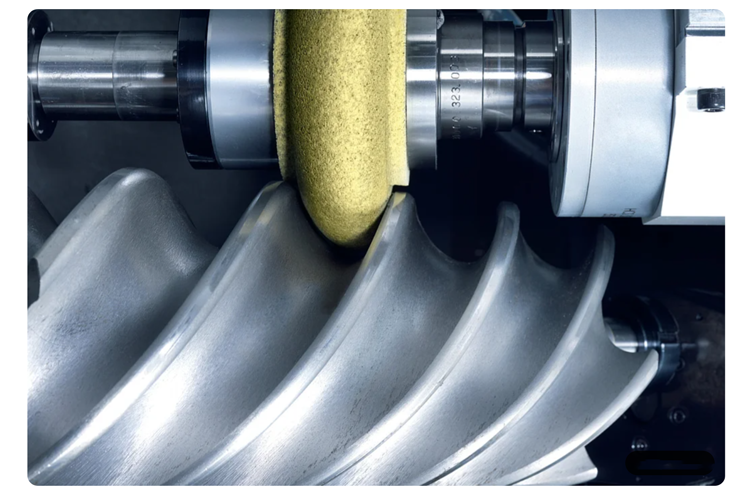

Forged screw rotor pair after precision grinding – mirror finish and perfect mating

Ready to Upgrade Your Compressor Performance?

Whether you need replacement rotors, new designs, or reverse engineering of legacy profiles, WALKSON has the forging expertise and Holroyd HG500 precision to deliver superior results.

Explore our screw rotor forging and machining capabilities here:

→Closed Die Forging Services

→ CNC Grinding Services

→ Contact WALKSON Engineering Team

When only the best precision will do, choose the team that grinds with the best — choose WALKSON.

Share this post if you're tired of compromising on rotor quality!

English

English  Deutsch

Deutsch  français

français  русский

русский  فارسی

فارسی  العربية

العربية  Español

Español  日本語

日本語  한국어

한국어  italiano

italiano  português

português  dansk

dansk  Suomi

Suomi