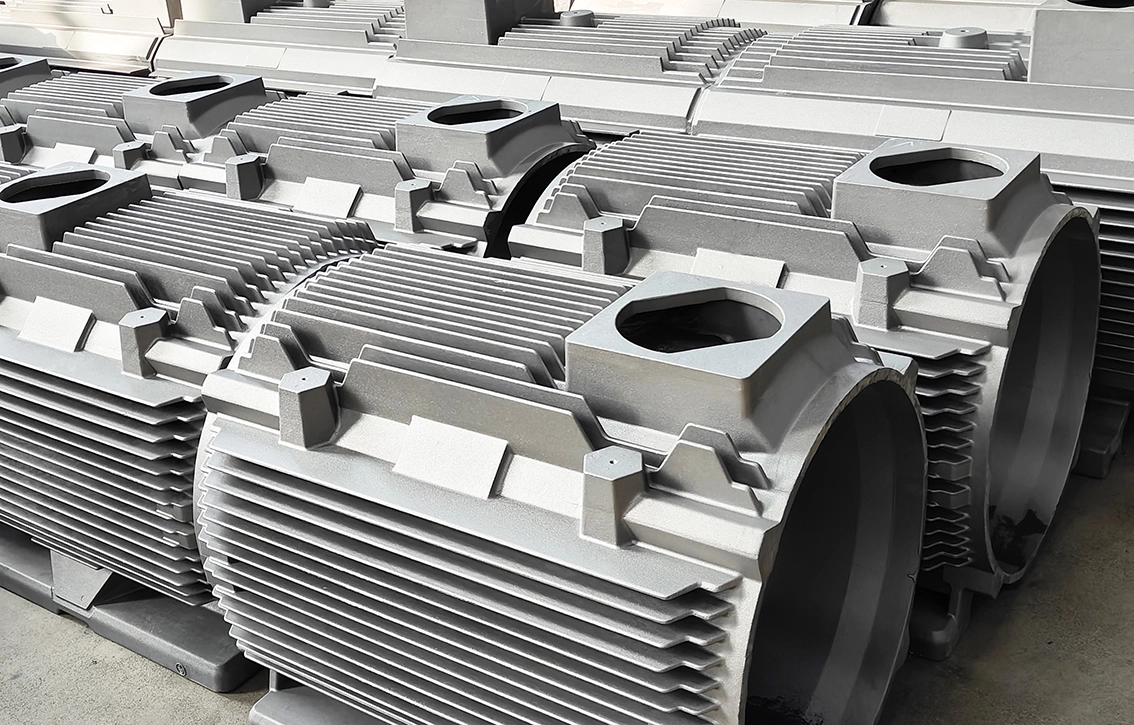

Roots Blower Bearing Housing by WALKSON

Function

The Roots Blower Bearing Housing Casting supports and aligns the bearings that facilitate rotor rotation within the blower. It maintains precise rotor positioning, absorbs operational stresses, and protects bearings from contaminants and excessive loads. By ensuring smooth and stable rotor operation, the bearing housing is essential for minimizing vibration, reducing wear, and extending the blower’s lifespan. Given its critical role in maintenance and repair, bearing housings are in high demand in industrial markets.

Specific Design

WALKSON’s bearing housings are engineered for precision and durability, featuring tight tolerances and robust construction to withstand high loads and harsh conditions. The design includes mounting surfaces for secure attachment to the blower’s end plates and precise bores for bearing installation, ensuring optimal alignment and performance. Custom configurations are available to match specific blower models or application needs, enhancing compatibility and functionality. The housings are designed to dissipate heat and resist corrosion, with reinforced structures for added strength. Advanced CAD modeling ensures a perfect fit and reliable operation.

Material Grades

WALKSON offers Roots Blower Bearing Housing Castings in high-quality materials compliant with international standards, selected for their strength, durability, and performance:

· Gray Iron: Conforms to ASTM A48 (e.g., Class 30, tensile strength 30,000 psi) and EN 1561 (e.g., EN-GJL-200). Gray iron provides excellent machinability, vibration damping, and cost-effectiveness, ideal for standard applications (ASTM A48, EN 1561).

· Ductile Iron: Meets ASTM A536 (e.g., 65-45-12, balancing strength and ductility) and EN 1563 (e.g., EN-GJS-400-15). Ductile iron offers superior toughness and wear resistance for high-load or abrasive environments (ASTM A536, EN 1563).

· Custom Alloys: Stainless steel or other specialized alloys are available for corrosive or high-temperature applications, tailored to client specifications.

Material selection is based on operational requirements, ensuring optimal performance and longevity.

Modern and Standardized Manufacturing Process

WALKSON employs a state-of-the-art manufacturing process to produce high-quality bearing housings:

· Pattern Making: Precision patterns are created using CAD and CNC machining for accurate mold formation.

· Casting: Sand casting is used for cost-effectiveness, while investment casting is employed for complex geometries requiring high precision.

· Machining: Advanced CNC machining centers ensure precise finishing, achieving tight tolerances and smooth surfaces for bearing alignment and mounting.

· Quality Control: Rigorous inspections at each stage, from material verification to final dimensional checks, ensure defect-free components.

The process is standardized to ensure consistency, repeatability, and compliance with customer specifications.

International Standards

WALKSON adheres to globally recognized standards throughout production:

· ASTM A48: Specifies requirements for gray iron castings, ensuring tensile strength and machinability (ASTM A48).

· ASTM A536: Governs ductile iron castings, ensuring high strength and ductility (ASTM A536).

· EN 1561: Details properties for gray cast iron with lamellar graphite (EN 1561).

· EN 1563: Specifies requirements for spheroidal graphite cast irons (EN 1563).

· ISO 9001: Ensures robust quality management systems across all production stages (ISO 9001).

These standards guarantee that WALKSON’s bearing housings meet the highest quality and performance criteria for global industrial applications.

Manufacturing and Inspection Equipment

WALKSON utilizes cutting-edge equipment to ensure precision and quality:

· CNC Machining Centers: For high-precision finishing, ensuring accurate bearing bores and mounting surfaces.

· Coordinate Measuring Machines (CMM): Verify dimensional accuracy, ensuring compliance with design specifications.

· Spectrometers: Analyze chemical composition to confirm material compliance with ASTM and EN standards.

· Hardness Testers: Rockwell or Brinell testers ensure material hardness meets wear resistance requirements.

· Surface Roughness Testers: Profilometers measure surface finish, critical for bearing performance.

· Ultrasonic Testing Equipment: Detects internal defects non-destructively, ensuring structural integrity.

This equipment ensures every bearing housing meets stringent quality standards.

Applicable Testing Procedures

WALKSON implements comprehensive testing protocols to ensure bearing housings meet performance and quality requirements:

· Tensile Testing: Conducted using universal testing machines to verify material strength, as per ASTM A48 and ASTM A536 standards.

· Hardness Testing: Performed with Rockwell or Brinell testers to confirm compliance with EN 1561 and EN 1563 hardness requirements.

· Dimensional Inspection: CMM ensures precise dimensions, bearing bores, and mounting surfaces, ensuring compatibility with blower systems.

· Load Testing: Simulates operational loads to verify structural integrity, using hydraulic test rigs.

· Non-Destructive Testing (NDT): Ultrasonic testing detects internal defects, following ASTM E114 and EN 12668 standards, using ultrasonic flaw detectors.

· Surface Finish Inspection: Profilometers verify surface roughness, ensuring optimal bearing performance.

These tests are conducted as required by applicable standards, with detailed documentation provided. Clients can witness testing, and third-party inspectors designated by the client are welcomed to ensure transparency and trust.

Industry Applications and Relevance

WALKSON’s Roots Blower Bearing Housing Castings are vital for a wide range of industries, ensuring reliable performance in demanding environments:

· Wastewater Treatment: Supports aeration systems for sewage treatment, ensuring consistent airflow.

· Pneumatic Conveying: Facilitates material handling in food, pharmaceutical, and chemical industries.

· Chemical Processing: Handles corrosive gases, requiring robust bearing housings.

· Combustion Air Supply: Powers industrial furnaces and burners for efficient combustion.

· Vacuum Systems: Used in manufacturing and packaging for vacuum applications.

· Mining: Enables dust collection and ventilation for safe operations.

· Environmental Control: Supports air pollution control systems for sustainability.

· Industrial Drying: Powers drying processes in manufacturing.

· HVAC Systems: Ensures air circulation in large buildings.

· Aquaculture: Provides aeration for fish farming, supporting aquatic ecosystems.

These castings are compatible with leading brands like Roots®, ensuring seamless integration into existing systems and meeting diverse industrial needs.

Quality Assurance Processes

WALKSON employs rigorous quality assurance processes to deliver reliable bearing housings:

· PPAP (Production Part Approval Process): Validates production processes through documentation and sample testing, ensuring customer requirements are met.

· FAT (First Article Inspection): Verifies the first production run against specifications before full-scale production.

· PFMEA (Process Failure Mode and Effects Analysis): Identifies and mitigates potential manufacturing risks, enhancing reliability.

· APQP (Advanced Product Quality Planning): Ensures quality through structured planning from design to production.

Clients can witness these tests, and third-party inspectors are accommodated, reflecting WALKSON’s commitment to transparency and quality.

Compatibility and Customization

WALKSON’s bearing housings are designed for compatibility with leading Roots Blower brands, including Roots®, ensuring easy integration into existing systems. Customization options are available, allowing clients to specify material grades, bore sizes, or mounting configurations to meet unique application needs, enhancing performance and flexibility.

Advantages of Buying from WALKSON

· Industry Expertise: Decades of experience in casting and machining deliver top-quality Roots Blower Bearing Housings tailored to industrial demands.

· Custom Solutions: Tailored designs and materials ensure optimal performance and compatibility for specific applications.

· Global Reach: Serving international markets with timely delivery and responsive customer service, fostering seamless partnerships.

· Uncompromising Quality: Comprehensive testing and adherence to ASTM, EN, and ISO standards guarantee reliability, with client and third-party oversight welcomed.

· Innovative Approach: Continuous process improvements provide cutting-edge solutions for modern industrial challenges.

Contact Information

For inquiries or to order Roots Blower Bearing Housing Castings, contact WALKSON:

· Email: info@walkson.com (mailto:info@walkson.com)

· WhatsApp/WeChat: +86 188 6716 5932

Choose WALKSON for Roots Blower Bearing Housing Castings that combine quality, reliability, and global expertise, ensuring your blower systems perform at their best.

English

English  Deutsch

Deutsch  français

français  русский

русский  فارسی

فارسی  العربية

العربية  Español

Español  日本語

日本語  한국어

한국어  italiano

italiano  português

português  dansk

dansk  Suomi

Suomi